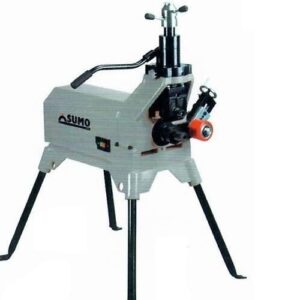

Pipe Grooving Machine

Pipe Grooving Threading Machine Supplier

Reliable Pipe Grooving Threading Machine Supplier – Yusufally And Sons

Looking for an efficient and long-lasting solution for pipe joining and fabrication? Yusufally And Sons is a leading Pipe Grooving Threading Machine Supplier, providing top-grade machinery for professionals in plumbing, firefighting, HVAC, and industrial fabrication sectors across Kolkata, West Bengal, Bihar, Odisha, Jharkhand, Chhattisgarh, and Assam.

Our grooving and threading machines offer high precision, heavy-duty performance, and ease of operation — suitable for GI, MS, SS, and PVC pipes. Whether you’re working on-site or in a fabrication workshop, our equipment ensures accurate pipe preparation and superior end-finishing every time.

What is a Pipe Grooving Threading Machine?

A pipe grooving threading machine is used for two key purposes:

Grooving – Cutting a circular groove on the outer diameter of the pipe for clamp-based joints or couplings

Threading – Creating external threads on pipe ends to connect with sockets or fittings

This dual-function machine is essential in firefighting lines, sprinkler systems, plumbing installations, gas pipelines, and industrial piping setups.

Types of Pipe Grooving & Threading Machines We Supply

Pipe Grooving Machine RX-12E

Specifications

Model | RX-12E |

Capacity | 2”-6” for schedule 40 8”-12” for schedule 10 |

Motor | 750W |

Voltage | 220V-240V, 50Hz |

Speed | 24RPM |

G.W: | 150 Kg |

Standard Accessories | ● Pipe Support Stand ● Pinch Roller 2”-6” – One pc ● Pinch Roller 8”-12” – One pc ● Knurling Wheel 2”- 3” – One pc ● Knurling Wheel 4”- 6” – One pc ● Knurling Wheel 8”- 12” – One pc |

Manual Pipe Threader 1 INCH

Specifications

Model | NV-62 |

Capacity | 1/2″ – 1” (BSPT) |

Die Head | 1/2″ , 3/4″ , 1” |

Model | NV-5A |

Capacity | 1”- 6” (Ø33- Ø168) SCH40 Pipe |

Max Wall Thickness | 6mm |

Voltage | 220V-240V, 50Hz |

Speed | 23RPM |

G.W | 96 Kg |

Standard Accessories | ● Pipe Support Stand ● Knurling Wheel Ø 33 – Ø 48 One pc ● Knurling Wheel Ø 57 – Ø 89 One pc ● Knurling Wheel Ø 108– Ø 168 One pc ● Pinch Roller Ø 33 – Ø 48 One pc ● Pinch Roller Ø 57 – Ø 168 One pc ● Groove Measuring Tape One pc |

Packaging Size | 95×53×65 (cm)

|

Model | NV-9A |

Capacity | 1”- 8” ( Ø33 – Ø219) SCH40 Pipe |

Max Wall Thickness | 8mm |

Voltage | 220V-240V, 50Hz |

Speed | 23RPM |

G.W | 98Kg |

Standard Accessories | ● Pipe Support Stand ● Knurling Wheel Ø 33 – Ø 48 One pc ● Knurling Wheel Ø 57 – Ø 89 One pc ● Knurling Wheel Ø 108– Ø 168 One pc ● Knurling Wheel Ø 219 One pc ● Pinch Roller Ø 33 – Ø 48 One pc ● Pinch Roller Ø 57 – Ø 168 One pc ● Pinch Roller Ø 219 One pc ● Groove Measuring Tape One pc |

Packaging Size | 95×53×65 (cm) |

Model | NV-2A |

Capacity | 2” – 12” (Ø60 – Ø325) SCH40 Pipe |

Max Wall Thickness | 10mm |

Voltage | 220V-240V, 50Hz |

Speed | 23RPM |

G.W | 163 Kg |

Standard Accessories | ● Pipe Support Stand ● Knurl Wheel Ø 60 – Ø 76 One pc ● Knurl Wheel Ø 89 – Ø 168 One pc ● Knurl Wheel Ø 219– Ø 325 One pc ● Pinch Roller Ø 60 – Ø 168 One pc ● Pinch Roller Ø 219 – Ø 325 One pc ● Groove Measuring Tape One pc ● Foot Switch One pc |

Packaging Size | 78×72×92 (cm) |

Socket Welding

Specifications

Model : PPR 63 | |

Fusion Range | Dia (MM ) : 20, 25, 32, 40, 50, 63 |

Rated Power | 800W |

Rated Voltage | 220V |

Frequency | 50/60Hz |

Working Temperature | 240-280° C |

Model : PPR 110 | |

Fusion Range | Dia (MM ) : 75, 90, 110 |

Rated Power | 1200W |

Rated Voltage | 220V |

Frequency | 50/60Hz |

Working Temperature | 240-280° C |

Hydraulic Pipe NV-4A

Specifications

MODEL | NV-4A |

Capacity | 8”-24” (Ø219 – Ø630) SCH40 Pipe |

Max Wall Thickness | 13mm |

Voltage | 380V-415V,50Hz |

Speed | 15RPM |

G.W | 340 Kg |

Standard Accessories | ● Hydraulic Pipe Support Stand ● Knurl Wheel Ø 219 – Ø 325 One pc ● Knurl Wheel Ø 377 – Ø 426 One pc ● Knurl Wheel Ø 480 – Ø 630 One pc ● Pinch Roller Ø 219 – Ø 530 One pc ● Pinch Roller Ø 630 One pc ● Groove Measuring Tape One Pc

|

Packaging Size | 102x75x147 (cm) |

Key Features of Our Machines

Precision die heads and cutters

High-speed operation with overload protection

Foot pedal (in some models) for hands-free operation

Stable base and anti-vibration frames

Self-lubricating threading dies

Interchangeable parts for different pipe sizes

Each unit we supply is selected for accuracy, repeatability, and low maintenance, ensuring long-term productivity.

Industries We Serve

Our machines are trusted by professionals in:

Plumbing & sanitary contracting

Firefighting and sprinkler system installations

Infrastructure & construction firms

Oil & gas pipeline maintenance

Facility management and MEP contractors

Tool rental companies and industrial workshops

Why Choose Yusufally And Sons?

✔️ Authorised Supplier of Leading Brands

✔️ Models Available in Manual, Semi-Automatic & Fully Automatic Variants

✔️ Genuine Products with Warranty & After-Sales Support

✔️ Ready Stock of Spares, Dies & Cutters

✔️ Dealer & Bulk Order Support Available

✔️ Fast Delivery to Remote and Metro Locations

As a trusted Pipe Grooving Threading Machine Supplier, we understand the needs of both field technicians and workshop operators, offering tools that are durable, user-friendly, and cost-effective.

Delivery Locations Covered

📍 West Bengal – Kolkata, Siliguri, Asansol, Durgapur

📍 Bihar – Patna, Gaya, Muzaffarpur, Bhagalpur

📍 Odisha – Bhubaneswar, Rourkela, Cuttack

📍 Jharkhand – Ranchi, Jamshedpur, Dhanbad

📍 Chhattisgarh – Raipur, Bilaspur, Bhilai

📍 Assam – Guwahati, Dibrugarh, Silchar

Our wide network ensures quick shipping and dependable technical support across Eastern India.

Contact Yusufally And Sons Today

Need a dependable Pipe Grooving Threading Machine Supplier for your business? Contact Yusufally And Sons today for the latest models, attractive pricing, and professional support.

📞 Call : +91 9007306745

✉️ Email : info@yusufallysons.com