Fastering & Fixing Machine

Fastering & Fixing Machine Supplier

Trusted Fastening & Fixing Machine Supplier in Eastern India – Yusufally And Sons

From carpentry to concrete work, fastening and fixing machines are essential tools across multiple industries. As a leading Fastening & Fixing Machine Supplier, Yusufally And Sons offers a premium range of fastening solutions to clients across Kolkata, West Bengal, Bihar, Odisha, Jharkhand, Chhattisgarh, and Assam.

We supply manual, pneumatic, and electric tools that simplify anchoring, joining, and mounting jobs in the fields of construction, furniture making, HVAC installation, and general maintenance. Our machines improve speed, accuracy, and strength — helping you complete fixing and fastening tasks in record time.

Product Description

The Festering & Fixing Machine is designed to streamline industrial Fastening and Fixing Processes, providing reliable performance for a variety of materials and applications.

Key Features:

- Robust Construction: Built with high-grade materials for longevity and resistance to wear and tear.

- High Efficiency: Delivers excellent fastening and fixing speeds to boost productivity.

- Precision Engineering: Ensures accurate fixing, reducing errors and material wastage.

- Versatility: Compatible with a wide range of fastening components and materials.

- User-Friendly Interface: Easy-to-use controls for hassle-free operation.

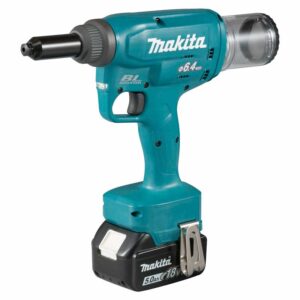

DRV250

Specifications

- 18V LXT BL Brushless Cordless Rivet Gun

- Jaw Case Designed to Enable Tight Space Operation

- The short center height allows for tight space operation such as close-to-wall riveting

- Compatible with various sizes of blind rivets

- A wide range of nose pieces and jaw pushers allow for tightening various sizes of blind rivets

- Compatible rivet diameter: ø4.8mm, ø6.0mm, ø6.4mm

- High speed tightening; Able to tighten rivets as fast as the competitors

- Rivet holding mechanism; Once a rivet is installed, it is held in place and do not drop out even when the tool is directed downward; No need for holding the rivet by hand even in vertical down application

- Transparent mandrel container; The amount of spent mandrels can be checked

- BL motor delivers 20 kN of max pulling force

- BL motor eliminates carbon brushes, enabling the BL motor to run cooler and more efficiently for longer life

- Twin LED job light with pre-glow and afterglow functions illuminates the work area

- Electric brake for maximum productivity

- Extreme Protection Technology (XPT) is engineered for improved dust and water resistance for operation in harsh conditions

- Battery protection circuit protects against overloading, over-discharging and over-heating

DRV150

Specifications

- 18V LXT BL Brushless Cordless Rivet Gun

- Jaw Case Designed to Enable Tight Space Operation

- The short center height allows for tight space operation such as close-to-wall riveting

- Compatible with various sizes of blind rivets

- A wide range of nose pieces and jaw pushers allow for tightening various sizes of blind rivets

- Compatible rivet diameter: ø2.4mm, ø3.2mm, ø4.0mm, ø4.8mm

- High speed tightening; Able to tighten rivets as fast as the competitors

- Higher speed riveting than DRV250

- Rivet holding mechanism; Once a rivet is installed, it is held in place and do not drop out even when the tool is directed downward; No need for holding the rivet by hand even in vertical down application

- Transparent mandrel container; The amount of spent mandrels can be checked

- BL motor delivers 10 kN of max pulling force

- BL motor eliminates carbon brushes, enabling the BL motor to run cooler and more efficiently for longer life

- Twin LED job light with pre-glow and afterglow functions illuminates the work area

- Electric brake for maximum productivity

- Extreme Protection Technology (XPT) is engineered for improved dust and water resistance for operation in harsh conditions

- Battery protection circuit protects against overloading, over-discharging and over-heating

DTR180

Specifications

- 18V LXT BL Brushless Cordless Rebar Tying Tool

- Tying Rebars Automatically

- Tying rebars can be done automatically in a various range of applications such as building concrete foundations

- Operable by only one hand, allowing the other hand to be free to adjust the position of rebar

- Continuous actuation mode for efficient continuous tying

- Users can tie rebars by only pulling contact arm against rebars if they continuously hold the trigger

- Users can also tie rebars by pulling the trigger as single actuation mode

- According to the condition of tying material, tying strength can be adjusted in 6 stages

- Compatible with both 18V & 14.4V LXT batteries

- Extreme Protection Technology (XPT) is engineered for improved dust and water resistance for operation in harsh conditions

- BL motor with high power to weight and size ratio

- BL motor generates less heat buildup and is ideal for prolonged use in high production applications

- BL motor eliminates carbon brushes, enabling the BL motor to run cooler and more efficiently for longer life

- According to the condition of tying material, tying strength can be adjusted in 6 stages

- φ0.8 mm Annealed tie wire dedicated for DTR180

- Tie wire reel can be replaced simply by opening Reel cover in the same way as competitor

- On-tool storage of hex wrench: Hex wrench is supplied for maintenance of tie wire path

- Main switch with auto power-off: Operation starts by pulling trigger after main switch is turned on

- Ergonomically designed handle with sure grip provides increased comfort on the job

DTR181

Specifications

- 18V LXT BL Brushless Cordless Rebar Tying Tool

- Applicable to large diameter rebars

The tool tip portion of tying mechanism is redesigned from DTR180 to enable to tie large diameter rebars that the current model cannot - Compatible with thick rebars (D22 x D25)

- Extension handle available as option allows you to operate in a stand-up position, reducing lower back strain

- 6-stage adjustable tying strength

Tying strength can be adjusted to suit the combination of rebars simply by operating the panel located above the battery - Tying rebars automatically

- Tying rebars can be done automatically in a various range of applications such as building concrete foundations

- Operable by only one hand, allowing the other hand to be free to adjust the position of rebar

- Continuous actuation mode for efficient continuous tying

- Users can tie rebars by only pulling contact arm against rebars if they continuously hold the trigger

- Users can also tie rebars by pulling the trigger as single actuation mode

- According to the condition of tying material, tying strength can be adjusted in 6 stages

- Extreme Protection Technology (XPT) is engineered for improved dust and water resistance for operation in harsh conditions

- BL motor with high power to weight and size ratio

- BL motor generates less heat buildup and is ideal for prolonged use in high production applications

- BL motor eliminates carbon brushes, enabling the BL motor to run cooler and more efficiently for longer life

FN001G

Specifications

- 40Vmax XGT BL Cordless 18 Ga 40 mm (1-5/8″) Brad Nailer

- 40Vmax XGT BL Cordless 18 Ga 40 mm (1-5/8″) Brad Nailer

- Compact design for high maneuverability

- High power to drive brad nails up to 40 mm; 35 mm into hard materials such as red oak

- Drives 6 different lengths of 18 gauge pin nails (15 mm (5/8″), 20 mm (3/4″), 25 mm (1″), 30 mm (1-3/16″), 35 mm (1-3/8″) and 40 mm (1-5/8″)); magazine capacity up to 100 nails

- Quick firing thanks to BL motor

- BL motor quickly re-compresses the spring for next firing

- Slim nose enables to drive nails securely into groove of narrow baseboard like 4 mm

- Contact arm mechanism enables “continuous nailing” and “drag nailing”

- Anti-dry fire mechanism engineered to minimize driving blanks and damage to work surface

- Toolless depth adjustment for precise flush and countersink finish

- Built-in LED light illuminates the work area

- Well-balanced design for reduced operator fatigue

- Ergonomically designed handle with soft grip provides increased comfort

- Spring-loaded driving mechanism allows for a compact tool with light weight

- Trigger-lock button minimizes accidental start up

- Battery protection circuit protects against overloading, over-discharging and over-heating

- Durable, reversible belt clip convenient for temporary tool hanging

AF506

Specifications

- 18 Ga 50 mm (2″) Pneumatic Brad Nailer, Air Duster

- Lightweight at Only 1.3 kg (2.9 lbs) for Increased Maneuverability

- Air duster for sweeping up job site floor as well as workpieces

- Compatible with EN ISO11148-13

- Slim soft grip provides increased comfort

- Drives a range of 18 gauge brad nails, from 15mm (5/8″) to 50mm (2″), into hard or soft wood applications; magazine capacity is up to 100 nails

- Quick-release cam-lock opens nail guide assembly to easily clear jammed nails; efficient design minimizes downtime

- Easy to use “tool-less” depth adjustment dial for a wide variety of finish applications

- Clear window allows operator to see number of remaining staples

- Easy-to-see slim nose tip allows quick and easy access to a desired fastening point

- Nose adapter for preventing workpiece surface from being scratched or damaged

- Non-marring rubber nose and bumpers protect the wood’s surface from being scratched or damaged

- Tool hook is convenient for hanging the tool temporarily

PT354D

Specifications

- 12V max CXT Li-Ion Cordless 23 GA 35 mm (1-3/8″) Pin Nailer

- Low Reaction Force Mechanism Enables Easier Long Pin Nailing and High-Quality Finish

- Easy-to-see slim nose tip allows quick and easy access to a desired fastening point

- Nails can be fired in the groove of baseboard

- Shoots 2,500 nails on a single full BL1041B charge

- Contact arm mechanism enables “continuous nailing” and “drag nailing”

- Contact trigger for improved accuracy and precision

- Drives 5 different lengths of 23 gauge pin nails (15 mm (5/8″), 18 mm (11/16″), 25 mm (1″), 30 mm (1-3/16″) and 35 mm (1-3/8″)); magazine capacity up to 120 nails

- Anti-dry fire mechanism engineered to prevent driving blanks and damage to work surface

- Toolless depth adjustment for precise flush and countersink finish

- Built-in LED light illuminates the work area

- Ergonomically designed handle with soft grip provides increased comfort

- Spring-loaded driving mechanism allows for a more compact tool with less weight

- Battery fuel gauge indicates battery charge level

- Nose adapter for driving pin nails on delicate surfaces

- Trigger-lock button prevents accidental start up

- Sight window for checking the amount of remaining pin nails

- Onboard hex wrench for keeping it from lost

- Battery protection circuit protects against overloading, over-discharging and over-heating

- Cordless for increased convenience; eliminates the need for a compressor and air hose. Durable, reversible belt clip convenient for temporary tool hanging. Slide style battery and improved ergonomic grip. Multi-contact terminals ensure stable contact with battery. Part of the expanding 12V max CXT series, combining performance with superior ergonomics in a compact size

Applications:

- Manufacturing units for assembling components.

- Construction and fabrication industries.

- Automotive and aerospace sectors.

Top Benefits of Choosing Festering & Fixing Machine

- Enhanced Productivity: Speeds up the fastening and fixing process, saving time and effort.

- Cost-Effective: Reduces material wastage and operational costs.

- Improved Accuracy: Delivers consistent results, minimizing errors in assembly tasks.

- Customizable Options: Available in various specifications to suit different industrial requirements.

- Durable Design: Offers long-lasting performance even in demanding environments.

How We Ensure Customer Satisfaction

At Yusufally and Sons, customer satisfaction is our top priority. Here’s how we achieve it:

- High-Quality Products: Every machine undergoes stringent quality checks to meet industry standards.

- Competitive Pricing: We offer the best value for your investment without compromising on quality.

- Comprehensive Support: Our expert team provides guidance on selecting the right machine and offers after-sales service.

- On-Time Delivery: Efficient logistics ensure timely delivery to your location.

- Customer-Centric Approach: We listen to your needs and tailor our services accordingly.

Why Choose Yusufally and Sons for Festering & Fixing Machines

- Reputation for Excellence: With a proven track record, we are a trusted name in the industry.

- Wide Range of Options: Our extensive product lineup ensures you find the perfect solution for your needs.

- Expert Team: Our skilled professionals are always ready to assist with technical support and recommendations.

- Pan-India Presence: Serving multiple locations ensures convenient access to our products and services.

- Sustainability Commitment: We source eco-friendly and energy-efficient machines for a greener tomorrow.

Applications of Our Fastening & Fixing Tools

Furniture & Interior Woodwork

Wall Cladding & Drywall Mounting

Civil & Infrastructure Projects

HVAC & Duct Installation

Electrical & MEP Fittings

Packaging, Pallet, and Box Fixing

Our machines are used by contractors, engineers, technicians, and service teams for various fastening applications across industries.

Target Locations Across Eastern India

We deliver fastening tools to:

📍 West Bengal – Kolkata, Durgapur, Siliguri, Asansol

📍 Bihar – Patna, Gaya, Bhagalpur

📍 Odisha – Bhubaneswar, Cuttack, Rourkela

📍 Jharkhand – Ranchi, Dhanbad, Jamshedpur

📍 Chhattisgarh – Raipur, Bilaspur, Bhilai

📍 Assam – Guwahati, Silchar, Dibrugarh

With strong logistics and ready stock, Yusufally And Sons supports contractors and industries throughout the region.

Accessories & Consumables We Provide

Fastener nails, screws, and staples

Anchor bolts and chemical fixings

Tool oil and maintenance kits

Battery packs and chargers

Air hoses and compressors (for pneumatic tools)

We ensure full availability of consumables and spares, so your projects never stall due to tool downtime.

Contact Yusufally And Sons – Your Fastening Tool Expert

Looking for a professional Fastening & Fixing Machine Supplier in Eastern India? Get in touch with Yusufally And Sons — the name known for genuine tools, expert support, and prompt delivery.

📞 Call : +91 9007306745

✉️ Email : info@yusufallysons.com